Finally got started on the centerboard.

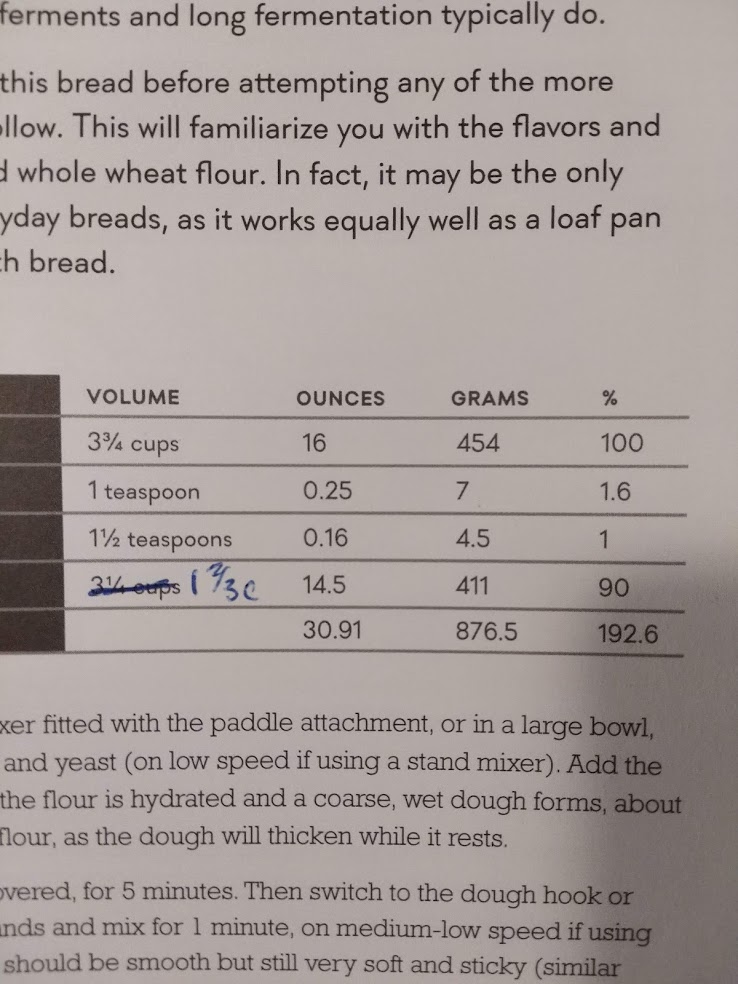

Routed out both halves to enclose the 22 lb steel plate, then coated both surfaces with epoxy before installing the plate.

Then I glued both halves together with copious amounts of epoxy and clamps. Not too much pressure with the clamps, as I didn’t want to squeeze out all of the glue. Epoxy does better when not glue starved.

I bought the centerboard and rudder pre-cut and shaped, but the CNC machine didn’t raise the cutter up high enough when transversing across the foil, so I got to try out mixing epoxy with wood flour. This was smoothed over the trough, and didn’t run out.

I couldn’t leave the void as the fiberglass wouldn’t dip down there completely, leaving an air filled void – not good on something constantly underwater – that void will attract water, and then rot out the centerboard.

Finally (for now), I coated both exterior sides with a coat of epoxy. When I get back to this I’ll apply two layers of 6 oz. fiberglass and quite a few more layers of epoxy.